The Long Road to Safety: 13 Years Prototyping the MyHerculead | E. Black & IAA

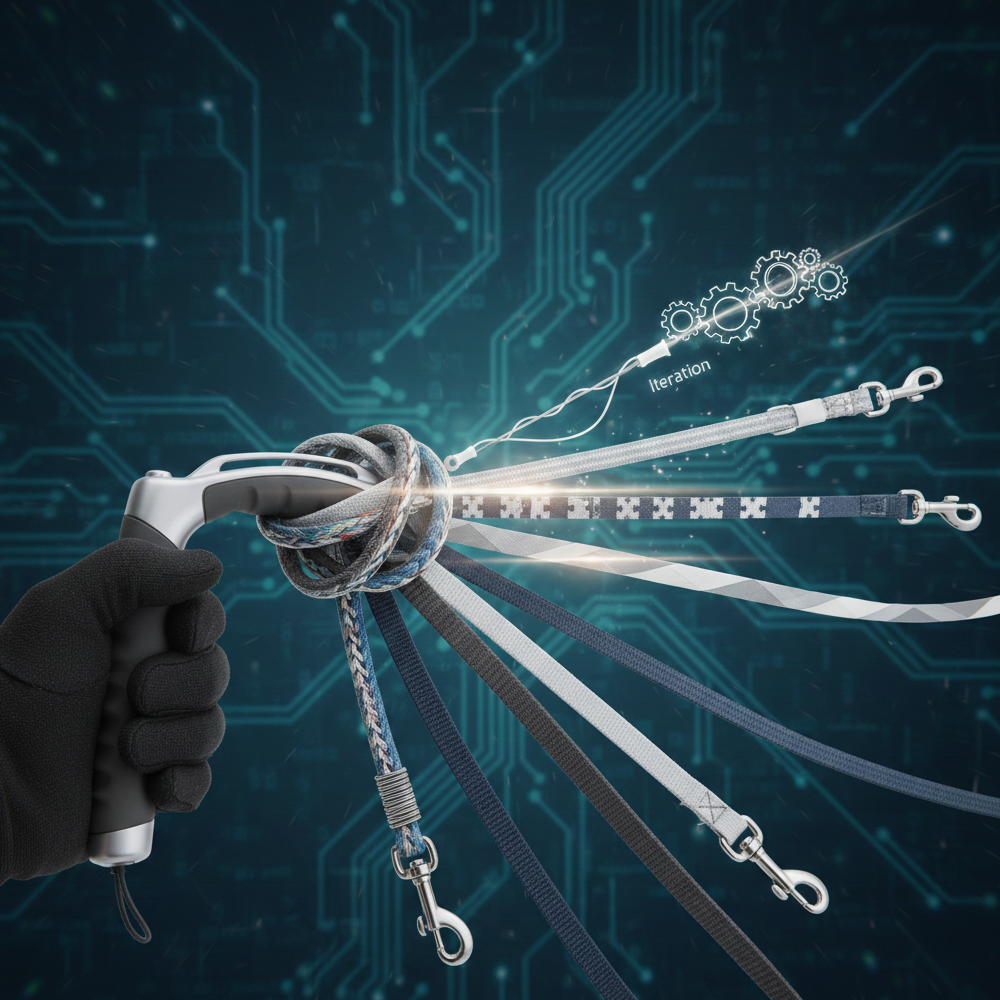

When I first began working on the MyHerculead — a multi-dog walking lead designed to be both anti-tangle and anti-twist — 13 years ago, I had a vision: a safer, more reliable way for people to walk multiple dogs without stress or injury.

Over a decade later, that vision has been tested not only by the laws of physics and the behaviors of multiple dogs, but also by the realities of independent invention: limited funds, material constraints, and the ever-present desire for perfection.

The Prototype Marathon

Over the past 13 years, I refined 69 iterations of the MyHerculead, each making small adjustments to ensure maximum safety and functionality for multiple dogs. Every tweak brought me closer to the final version we’ll be testing in 2026. After many iterations, we’ve finally reached a design that meets our strict safety and usability criteria. Each prototype revealed unexpected challenges:

Leash materials that frayed under stress

Clip mechanisms that could fail under sudden tension

Geometries that allowed tangles in multi-dog scenarios

Every failure wasn’t wasted; it was data. Documentation and hypothesis-driven prototyping — the core of the BH Methodology — ensured that every “wrong” design brought us closer to the right one.

Hurdles Beyond the Bench

Independent invention isn’t just about the technical challenges. Funding constraints delayed testing phases. Sourcing components took weeks longer than anticipated. And perfectionism — particularly when it concerns the safety of my own and other people’s dogs — meant nothing could be rushed.

Yet these hurdles taught lessons that no textbook could: patience, disciplined iteration, and the value of a repeatable process.

Looking Ahead

In 2026, we begin testing the final version of the MyHerculead. If outcomes align with expectations, we plan to move toward a launch shortly thereafter. This long arc of development reinforces one simple truth: independent inventors can achieve institutional-grade results, but only if they respect the process, document everything, and embrace iterative learning.

For other inventors, the takeaway is clear: each delay, each failed prototype, and each resource constraint is not a setback—it is an opportunity to refine your system and your methodology.